The Complete Water Damage Restoration Process: A Step-by-Step Guide

Understanding the water damage restoration process is essential for homeowners facing emergency water damage situations. Whether dealing with burst pipes, storm flooding, basement water intrusion, or appliance failures, knowing what to expect during professional restoration helps you make informed decisions, work effectively with restoration professionals, and ensure quality outcomes for your property. The restoration process involves multiple phases, specialized techniques, and quality control measures that transform water-damaged properties back to pre-loss condition while preventing future problems such as mold growth and structural damage.

As water damage restoration experts serving Garnet Valley and Delaware County, we understand that homeowners need clear information about the restoration process to feel confident during stressful emergency situations. Our partnership with RestoreMore365 has given us extensive experience in professional restoration procedures, and we’re committed to helping our neighbors understand what professional restoration involves and why each step is critical for successful outcomes.

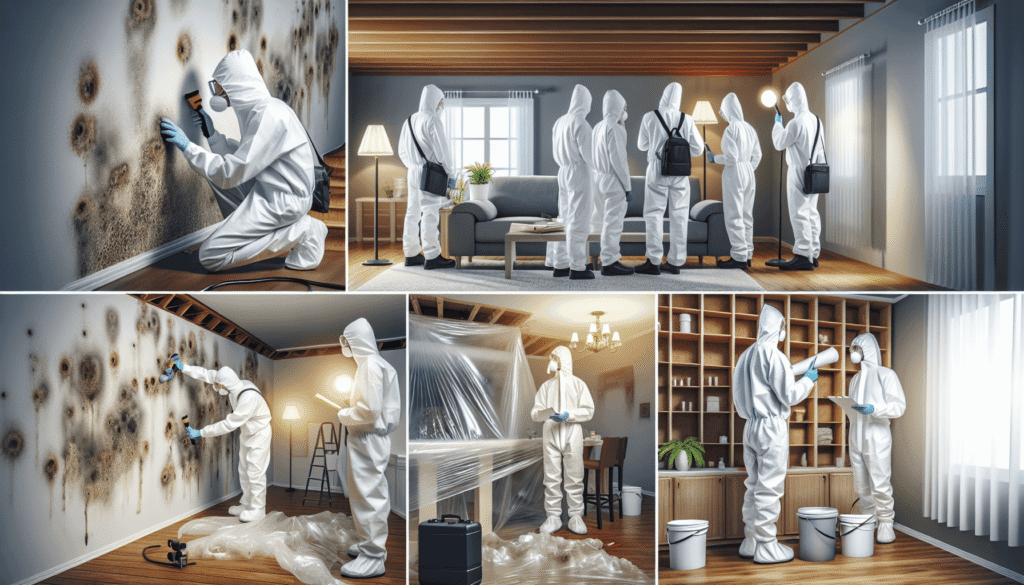

Overview of Professional Water Damage Restoration

Professional water damage restoration follows established industry standards and procedures developed by organizations such as the Institute of Inspection, Cleaning and Restoration Certification. These standards ensure consistent, effective restoration that addresses all aspects of water damage while protecting property and occupant health.

Industry Standards and Certification

IICRC Standards: The Institute of Inspection, Cleaning and Restoration Certification establishes industry standards for water damage restoration that professional companies follow to ensure quality outcomes. These standards cover assessment procedures, drying techniques, equipment requirements, and quality control measures that guide professional restoration work.

Restoration Principles: Professional restoration follows fundamental principles including rapid response, thorough assessment, appropriate equipment selection, continuous monitoring, and quality verification. These principles ensure that restoration work addresses all damage and prevents secondary problems such as mold growth.

Safety Protocols: Professional restoration companies follow comprehensive safety protocols that protect both workers and occupants during restoration work. These protocols are particularly important for contaminated water damage and situations involving electrical hazards or structural damage.

Documentation Requirements: Professional restoration involves detailed documentation of damage assessment, moisture readings, equipment placement, and progress monitoring. This documentation supports insurance claims and provides quality control throughout the restoration process.

Restoration Categories and Classifications

Water Damage Categories: Water damage is classified into three categories based on contamination level. Category 1 (clean water) from sources like supply line breaks requires standard restoration procedures. Category 2 (gray water) from sources like washing machine overflows requires additional safety measures and specialized cleaning. Category 3 (black water) from sewage backups or flood water requires extensive safety protocols and often complete material removal.

Damage Classes: The IICRC defines four classes of water damage based on evaporation rates and materials affected. Class 1 damage affects materials with low absorption rates and requires minimal equipment. Class 4 damage involves specialty materials like hardwood and plaster that require specialized drying techniques and extended restoration timelines.

Structural Impact Assessment: Professional restoration includes assessment of structural impact including foundation damage, framing issues, and building envelope compromise. Structural damage may require specialized repair techniques and coordination with structural engineers or other specialists.

Secondary Damage Evaluation: Professional restoration addresses secondary damage including mold growth, material deterioration, and system damage that can occur following initial water damage. Early identification and treatment of secondary damage prevents more extensive problems and higher restoration costs.

Phase 1: Emergency Response and Initial Assessment

Immediate Emergency Response

24/7 Emergency Availability: Professional restoration companies provide 24/7 emergency response to minimize damage and begin restoration procedures as quickly as possible. Rapid response is critical for preventing secondary damage and reducing overall restoration costs and timelines.

Initial Contact and Dispatch: Emergency response begins with initial contact assessment to determine the scope of emergency and appropriate response resources. Dispatch procedures ensure that qualified technicians with appropriate equipment respond to emergency situations promptly.

Safety Assessment and Securing: Upon arrival, restoration technicians conduct safety assessments to identify hazards such as electrical dangers, structural damage, or contamination risks. The property is secured and made safe for restoration work before beginning damage assessment procedures.

Emergency Mitigation Setup: Emergency mitigation includes immediate water extraction, emergency board-up services, and initial moisture control to prevent additional damage. These services stabilize the situation and create conditions for comprehensive restoration work.

Comprehensive Damage Assessment

Visual Inspection and Documentation: Comprehensive damage assessment begins with detailed visual inspection of all affected areas, including hidden spaces such as wall cavities and subfloor areas. All damage is documented with photographs and written descriptions that support restoration planning and insurance claims.

Moisture Detection and Mapping: Professional moisture detection uses specialized equipment including moisture meters, thermal imaging cameras, and hygrometers to identify all affected materials and create detailed moisture maps. This detection ensures that all damage is identified and addressed during restoration.

Structural Evaluation: Structural evaluation assesses the impact of water damage on building systems including framing, subflooring, and foundation elements. This evaluation determines whether structural repairs are needed and identifies any safety concerns that must be addressed.

Air Quality Assessment: Air quality assessment includes testing for mold spores, bacteria, and other contaminants that may affect indoor air quality. This assessment establishes baseline conditions and guides air quality management throughout the restoration process.

Restoration Planning and Scope Development

Comprehensive Restoration Plan: Based on damage assessment findings, restoration professionals develop comprehensive restoration plans that address all identified damage and establish timelines for completion. These plans serve as roadmaps for restoration work and communication tools for homeowners and insurance companies.

Equipment and Resource Planning: Restoration planning includes determining equipment requirements, material needs, and labor resources necessary for effective restoration. Proper planning ensures that all necessary resources are available and restoration work proceeds efficiently.

Insurance Coordination: Professional restoration companies coordinate with insurance companies to ensure that restoration plans align with policy coverage and claim requirements. This coordination includes providing detailed documentation and working with adjusters to establish appropriate claim settlements.

Timeline Development: Realistic timeline development considers the scope of damage, drying requirements, material availability, and reconstruction needs. Accurate timelines help homeowners plan for restoration disruption and coordinate temporary living arrangements if necessary.

Phase 2: Water Extraction and Removal

Professional Water Extraction Techniques

Truck-Mounted Extraction Systems: Professional water extraction uses powerful truck-mounted systems that provide superior extraction capability compared to portable equipment. These systems can remove large volumes of water quickly and efficiently, reducing drying time and preventing additional damage.

Portable Extraction Equipment: Portable extraction equipment is used in areas where truck-mounted systems cannot reach or for specialized extraction needs. This equipment includes submersible pumps, wet vacuums, and specialized extraction tools for different materials and situations.

Extraction Technique Selection: Professional technicians select appropriate extraction techniques based on water volume, contamination level, and affected materials. Different techniques are used for carpet extraction, hardwood floor extraction, and structural water removal to maximize effectiveness.

Safety Protocols During Extraction: Water extraction follows strict safety protocols including electrical safety measures, contamination protection, and structural safety considerations. These protocols protect both technicians and occupants during extraction procedures.

Contaminated Water Handling

Category 2 Gray Water Procedures: Gray water extraction requires additional safety measures including protective equipment, antimicrobial treatments, and specialized disposal procedures. These procedures prevent health risks and ensure proper handling of contaminated materials.

Category 3 Black Water Protocols: Black water extraction requires extensive safety protocols including full protective equipment, containment procedures, and specialized disposal methods. Black water situations often require complete material removal rather than restoration due to health risks.

Contamination Control Measures: Contamination control includes establishing containment barriers, using negative air pressure systems, and implementing decontamination procedures for equipment and personnel. These measures prevent contamination spread throughout the property.

Disposal and Environmental Compliance: Contaminated water and materials are disposed of according to environmental regulations and local requirements. Professional restoration companies ensure compliance with all applicable regulations and maintain proper documentation of disposal procedures.

Moisture Removal from Structural Materials

Structural Drying Preparation: Following water extraction, structural materials require specialized drying procedures to remove absorbed moisture. Preparation includes removing wet contents, creating access to wall cavities, and establishing optimal drying conditions.

Material-Specific Extraction: Different materials require specific extraction techniques. Carpet and pad extraction differs from hardwood floor extraction, which differs from drywall and insulation extraction. Professional technicians use appropriate techniques for each material type.

Hidden Moisture Detection: Professional extraction includes detecting and removing moisture from hidden areas such as wall cavities, subfloor spaces, and ceiling voids. Specialized equipment and techniques ensure that all moisture is identified and removed.

Progress Monitoring: Extraction progress is monitored using moisture meters and other instruments to ensure complete water removal. Monitoring continues throughout the extraction phase to verify effectiveness and guide additional extraction efforts if needed.

Phase 3: Structural Drying and Dehumidification

Professional Drying Equipment Setup

Industrial Dehumidification Systems: Professional drying uses industrial-grade dehumidifiers that provide superior moisture removal compared to consumer equipment. These systems are sized and positioned based on affected area volume, moisture load, and environmental conditions to achieve optimal drying performance.

High-Velocity Air Movement: Strategic air movement using industrial fans and air movers accelerates evaporation and moisture removal from structural materials. Air movement equipment is positioned to create optimal airflow patterns that maximize drying efficiency while minimizing energy consumption.

Specialized Drying Equipment: Specialized drying equipment includes injectidry systems for wall cavities, mat drying systems for hardwood floors, and heat drying systems for accelerated moisture removal. This equipment addresses specific drying challenges that standard equipment cannot handle effectively.

Environmental Controls: Professional drying includes environmental controls such as temperature management, humidity control, and ventilation systems that create optimal drying conditions. These controls ensure efficient drying while maintaining indoor air quality and occupant comfort.

Moisture Monitoring and Documentation

Daily Moisture Readings: Professional drying includes daily moisture readings using calibrated moisture meters to track drying progress and ensure complete moisture removal. These readings are documented and used to adjust equipment and procedures as needed.

Psychrometric Calculations: Psychrometric calculations determine optimal drying conditions and equipment requirements based on temperature, humidity, and moisture load factors. These calculations ensure that drying equipment is properly sized and positioned for maximum effectiveness.

Progress Documentation: Drying progress is documented with detailed logs that include moisture readings, equipment adjustments, and environmental conditions. This documentation supports insurance claims and provides quality control throughout the drying process.

Completion Verification: Drying completion is verified through comprehensive moisture testing that confirms all materials have reached acceptable moisture levels. Completion verification ensures that restoration can proceed without risk of future moisture problems.

Advanced Drying Techniques

Injectidry Systems: Injectidry systems use specialized equipment to dry wall cavities and other enclosed spaces without removing wall materials. These systems inject heated air into cavities and extract moist air, allowing drying of hidden areas that would otherwise require demolition.

Heat Drying Applications: Heat drying uses controlled temperature elevation to accelerate moisture removal from dense materials such as hardwood floors and plaster walls. Heat drying reduces drying time and improves outcomes for materials that respond well to temperature-enhanced drying.

Desiccant Dehumidification: Desiccant dehumidifiers use chemical moisture absorption to achieve very low humidity levels that conventional refrigerant dehumidifiers cannot reach. These systems are used for specialized applications requiring extreme moisture removal.

Freeze Drying Techniques: Freeze drying techniques are used for specialized applications such as document recovery and certain material types that benefit from sublimation drying processes. These techniques require specialized equipment and expertise but can achieve superior results for appropriate applications.

Phase 4: Cleaning and Sanitization

Structural Cleaning Procedures

Surface Cleaning and Preparation: Structural cleaning begins with thorough cleaning of all affected surfaces to remove contaminants, debris, and residues left by water damage. Surface preparation ensures that subsequent treatments and coatings will adhere properly and provide long-term protection.

Antimicrobial Treatment Application: Antimicrobial treatments are applied to affected surfaces to prevent mold growth and eliminate bacteria and other microorganisms. These treatments are selected based on surface materials and contamination levels to ensure effectiveness while maintaining material integrity.

HVAC System Cleaning: HVAC system cleaning includes ductwork cleaning, equipment sanitization, and filter replacement to prevent contamination spread and ensure indoor air quality. HVAC cleaning is particularly important following water damage to prevent mold growth in system components.

Specialized Cleaning Techniques: Specialized cleaning techniques are used for different materials and contamination types. These techniques include pressure washing, chemical cleaning, abrasive cleaning, and other methods selected based on material type and cleaning requirements.

Content Cleaning and Restoration

Content Assessment and Triage: Content cleaning begins with assessment and triage to determine which items can be restored, which require specialized treatment, and which must be replaced. This assessment considers item value, sentimental importance, and restoration feasibility.

On-Site Content Cleaning: On-site content cleaning includes cleaning of furniture, electronics, documents, and other items that can be effectively cleaned at the property. On-site cleaning is convenient and cost-effective for items that don’t require specialized facility treatment.

Off-Site Specialized Restoration: Off-site restoration facilities provide specialized cleaning for items requiring advanced techniques such as freeze drying, ultrasonic cleaning, or controlled environment processing. These facilities have equipment and expertise not available for on-site cleaning.

Content Storage and Management: Content storage and management includes secure storage of cleaned items during property restoration and systematic tracking of all items throughout the cleaning process. Proper management ensures that items are protected and returned to homeowners in good condition.

Air Quality Management

Air Scrubbing and Filtration: Air scrubbing systems use HEPA filtration to remove airborne contaminants including mold spores, bacteria, and particulates. These systems maintain indoor air quality during restoration work and prevent contamination spread to unaffected areas.

Negative Air Pressure Systems: Negative air pressure systems create controlled airflow that prevents contamination spread from affected areas to clean areas. These systems are particularly important for contaminated water damage and mold remediation situations.

Air Quality Testing: Air quality testing includes sampling for mold spores, bacteria, and other contaminants to verify that air quality meets acceptable standards. Testing is performed before, during, and after restoration to ensure occupant safety and restoration effectiveness.

Odor Control and Elimination: Odor control includes identification of odor sources, removal of odor-causing materials, and application of odor elimination treatments. Professional odor control addresses both surface odors and deep-seated odors that require specialized treatment techniques.

Phase 5: Reconstruction and Restoration

Reconstruction Planning and Coordination

Reconstruction Scope Development: Reconstruction planning begins with detailed scope development that identifies all materials and systems requiring replacement or repair. The scope considers building codes, permit requirements, and homeowner preferences for materials and finishes.

Permit and Code Compliance: Reconstruction work must comply with local building codes and permit requirements. Professional restoration companies coordinate with local authorities to ensure proper permits are obtained and work meets all applicable standards.

Material Selection and Procurement: Material selection considers quality, durability, and compatibility with existing building systems. Professional restoration companies help homeowners select appropriate materials that provide long-term performance and value.

Subcontractor Coordination: Complex reconstruction projects require coordination with specialized subcontractors including electricians, plumbers, and HVAC contractors. Professional restoration companies manage these relationships to ensure quality work and timely completion.

Structural Repairs and Replacement

Framing and Structural Work: Structural repairs include replacement of damaged framing members, subflooring, and other structural components. This work requires expertise in building construction and may require structural engineering consultation for complex damage.

Drywall and Interior Finishes: Drywall replacement includes proper installation, finishing, and texture matching to blend with existing surfaces. Professional installation ensures quality results that match pre-loss conditions and provide long-term durability.

Flooring Installation: Flooring installation includes subfloor preparation, moisture barrier installation, and finish flooring installation using appropriate techniques for each flooring type. Professional installation ensures proper performance and warranty compliance.

Trim and Millwork: Trim and millwork replacement requires skilled craftsmanship to match existing profiles and finishes. Custom millwork may be required for historic homes or unique architectural features that cannot be matched with standard materials.

Systems Restoration and Upgrades

Electrical System Restoration: Electrical system restoration includes replacement of damaged wiring, outlets, and fixtures while ensuring code compliance and safety. Electrical work must be performed by licensed electricians and inspected according to local requirements.

Plumbing System Repairs: Plumbing repairs address damage to supply lines, drain lines, and fixtures while ensuring proper operation and code compliance. Plumbing work includes pressure testing and inspection to verify system integrity.

HVAC System Restoration: HVAC system restoration includes equipment replacement, ductwork repair, and system balancing to ensure proper operation and efficiency. HVAC work may include upgrades to improve performance and prevent future water damage.

Insulation and Energy Efficiency: Insulation replacement provides opportunities for energy efficiency upgrades that improve comfort and reduce operating costs. Professional installation ensures proper performance and prevents moisture problems that could lead to future damage.

Phase 6: Quality Control and Final Inspection

Comprehensive Quality Verification

Moisture Level Verification: Final moisture verification ensures that all materials have reached acceptable moisture levels and that no hidden moisture remains that could cause future problems. Verification uses calibrated instruments and follows industry standards for acceptable moisture levels.

Workmanship Quality Inspection: Quality inspection includes detailed examination of all restoration work to ensure that it meets professional standards and matches pre-loss conditions. This inspection identifies any deficiencies that require correction before project completion.

System Performance Testing: System performance testing verifies that all building systems including electrical, plumbing, and HVAC operate properly following restoration work. Testing ensures that systems meet performance standards and safety requirements.

Air Quality Verification: Final air quality testing verifies that indoor air quality meets acceptable standards and that no contamination remains from the water damage incident. Air quality verification provides assurance that the property is safe for occupancy.

Documentation and Warranty

Completion Documentation: Completion documentation includes detailed records of all restoration work, material specifications, and quality verification results. This documentation supports warranty claims and provides valuable information for future reference.

Warranty Provision: Professional restoration companies provide warranties on their work that protect homeowners from defects and problems. Warranty terms vary based on work type and company policies but typically provide protection for workmanship and materials.

Maintenance Recommendations: Maintenance recommendations help homeowners protect their investment and prevent future water damage. These recommendations include routine maintenance schedules, system monitoring, and early warning signs of potential problems.

Insurance Claim Finalization: Insurance claim finalization includes providing final documentation to insurance companies and ensuring that all claim requirements are met. Professional restoration companies coordinate with adjusters to ensure proper claim closure and payment.

Final Walkthrough and Customer Education

Detailed Walkthrough Process: The final walkthrough includes detailed inspection of all restoration work with the homeowner to ensure satisfaction and identify any concerns. This process provides opportunity for questions and ensures that homeowners understand the work that was performed.

System Operation Education: Customer education includes instruction on proper operation of restored systems and equipment. This education helps homeowners maintain their systems properly and identify potential problems before they become major issues.

Prevention Education: Prevention education helps homeowners understand how to prevent future water damage through proper maintenance, monitoring, and early intervention. This education provides long-term value and helps protect the restoration investment.

Emergency Contact Information: Emergency contact information ensures that homeowners know how to reach professional help if future problems occur. This information includes 24/7 emergency contacts and guidance on when to call for professional assistance.

Timeline Expectations and Project Management

Typical Restoration Timelines

Emergency Response Phase: Emergency response typically occurs within 1-4 hours of initial contact, depending on time of day and weather conditions. Rapid response is critical for minimizing damage and beginning restoration procedures promptly.

Assessment and Planning Phase: Comprehensive assessment and restoration planning typically requires 1-2 days depending on damage complexity and property size. Thorough assessment is essential for developing effective restoration plans and accurate cost estimates.

Drying and Dehumidification Phase: Structural drying typically requires 3-7 days depending on materials affected, environmental conditions, and equipment capacity. Some materials such as hardwood floors or plaster may require longer drying periods to achieve acceptable moisture levels.

Reconstruction Phase: Reconstruction timelines vary significantly based on damage scope and complexity. Minor reconstruction may require 1-2 weeks, while extensive reconstruction can require several months for completion. Timeline factors include permit processing, material availability, and weather conditions.

Project Management and Communication

Daily Progress Updates: Professional restoration companies provide daily progress updates during active restoration work. These updates include moisture readings, equipment adjustments, and timeline updates that keep homeowners informed throughout the process.

Milestone Communication: Milestone communication includes notification of major project phases such as drying completion, reconstruction start, and final inspection scheduling. This communication helps homeowners plan for project progression and coordinate their schedules.

Problem Resolution: Professional project management includes prompt identification and resolution of problems that arise during restoration work. Effective problem resolution minimizes delays and ensures quality outcomes despite unexpected challenges.

Customer Service Support: Customer service support provides homeowners with single points of contact for questions, concerns, and coordination needs. Professional customer service ensures that homeowners receive prompt responses and effective problem resolution throughout the restoration process.

Conclusion

Understanding the complete water damage restoration process helps homeowners make informed decisions and work effectively with restoration professionals when water damage affects their properties. Professional restoration follows established procedures and quality standards that ensure effective damage remediation while protecting property value and occupant health.

Remember that professional restoration companies like RestoreMore365 provide expertise, equipment, and project management that ensure quality outcomes and customer satisfaction throughout the restoration process. When water damage affects your property, choose qualified professionals who follow industry standards and provide comprehensive restoration services from emergency response through final completion.

For more information about specific restoration services and emergency response, visit our comprehensive guides on emergency water damage response, basement water damage restoration, flood restoration services, storm damage cleanup, and burst pipe cleanup. These resources provide detailed information about specialized restoration services and help homeowners understand what to expect when professional restoration is needed.

Trust the restoration process to qualified professionals who understand the complexity of water damage restoration and provide quality service that protects your property, your family, and your investment. Professional restoration may seem complex, but it provides the expertise and quality assurance necessary for successful outcomes when water damage affects your home.